PANTEC Eagle 系列三坐标控制系统

来自瑞士PANTEC公司原装进口的三坐标测量机控制系统,开放式的控制平台,具有强劲的驱动能力,优秀的三轴控制定位及方便灵活的手控终端确保了高效的生产率;

目前三坐标CMM市场上常用的是Eagle 系列,EAGLE™ basic和EAGLE™ pro/3,(或Pro4)可根据设备的行程及负载来选用相应版本。

具体参数区别可点击下方 性能参数 选项卡进行查看

根据需要可配置Eagle PAD™ 操作手柄或无线 PAD PC 无线手柄。

PANTEC系统的主要特点是:

-可提升CMM性能-注重系统的连续性

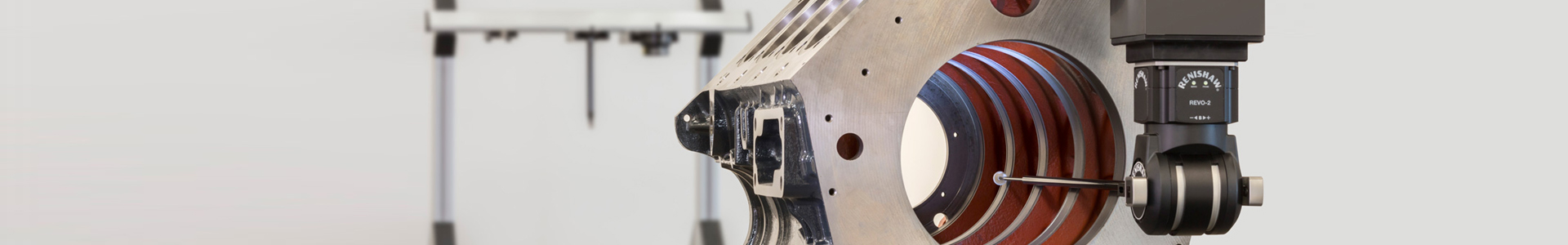

-持久有效的软硬件升级服务-配备最新测头系统集成

-支持全套的RENISHAW测头系统

-唯一支持Renishaw伺服测头系统PHS-1

-兼容多种CMM软件

-Eagle PAD手控终端

公司可为您提供全套的PANTEC控制系统,及多轴控制卡,扫描卡配件;

也可进行原老版本WPS 2030、2040及HT400的维修、置换服务。

| EAGLE™ basic | EAGLE™ pro/3 | ||

| Physical Data | Rack mounting | 19" | 19" |

| Weight | 10 kg | 20 kg | |

| Dimensions (W x D x H) | 490 x 90 x 380 mm | 490 x 135 x 380 mm | |

| Electrical Data | Nominal input power | 550 VA | 550 VA |

| Input voltage | 230 VAC (Art.no. 34607) 115 VAC (Art.no. 34608) | 230 VAC (Art.no. 34605) 115 VAC (Art.no. 34606) | |

| Main Axis | Servo loop time | 83 µs | 83 µs |

| Drive power | 4 A / 60 V | 5 A / 60 V | |

| Input frequency (digital scale) | up to 15 MHz | up to 15 MHz | |

| Digital scale input RS422 | ✓ | ✓ | |

| Number of main axis | 3 | 3 | |

| Analog scale input | by external interface | by external interface | |

| Feedback | Encoder / Tachometer | Encoder / Tachometer | |

| Motor Types | DC-Brush | DC-Brush | |

| Digital servo drives | up to 96 kHz PWM | up to 96 kHz PWM | |

| Subcount interpolation | ✓ | ✓ | |

| General Specifications | SP600 interface | n/a | ✓ (with Option board) |

| Number of CMM axes controlled | 3 | 3 | |

| SP80 interface | n/a | ✓ (with Option board) | |

| TP200 interface | ✓ (with Option Board) | ✓ (with Head interface) | |

| SP25M interface | n/a | ✓ (with Option board) | |

| Software integration | EAGLE.driver | EAGLE.driver | |

| Communications link with PC | Ethernet and RS232 | Ethernet and RS232 | |

| TP20 interface | ✓ | ✓ | |

| Ethernet communication rate | 100 Mbit/s | 100 Mbit/s | |

| Pantec Support Tool | ✓ | ✓ | |

| Emergency stop DIN EN 13849 | ✓ | ✓, extended | |

| Measurement volume | X+Y = 3800 mm / Z = 800 mm | unlimited | |

| GEC (Geometric Error Compensation) | ✓ | ✓ | |

| Touch-trigger probing function | ✓ | ✓ | |

| Temperature sensor inputs (T-Bus™) | 16 (with Option Board) | 16 | |

| Integrated motor power supply | ✓ | ✓ | |

| Configured for direct CNC controlled CMMs | ✓ | ✓ | |

| Configurable additional axis | n/a | n/a |